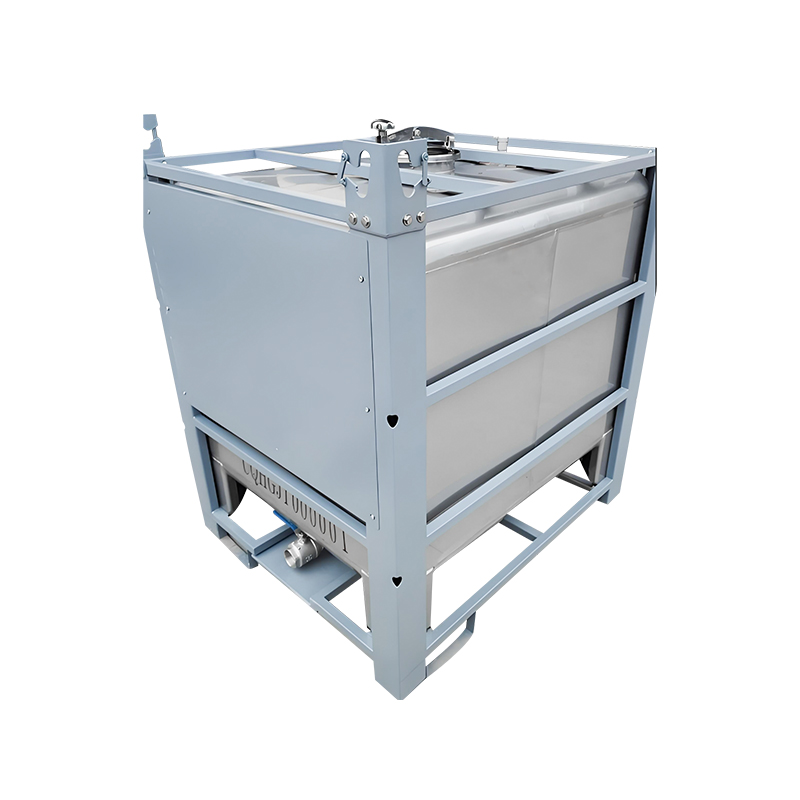

In the complex world of industrial logistics and processing, efficiency, safety, and product integrity are paramount. Among the many tools that facilitate these goals, the Stainless Steel Intermediate Bulk Container (IBC) tank stands out for its versatility and reliability. Far from being a simple storage vessel, it is an integrated system designed to handle a wide range of demanding substances.

Core Function 1: Secure and Sanitary Storage

The most fundamental role of any container is storage, and stainless steel IBCs excel in this area, particularly for sensitive or high-purity materials.

Long-Term Product Integrity: Unlike porous or reactive materials, 304 or 316-grade stainless steel is non-reactive. This prevents the container from interacting with the contents, ensuring that chemicals remain stable, food-grade products retain their purity, and pharmaceuticals are not contaminated by leaching. The hermetic seal provided by the tank and its closure system protects contents from external contaminants like moisture, dust, and airborne microbes.

Environmental Protection: A robust stainless steel IBC is a primary means of containment, safeguarding the surrounding environment from potential spills or leaks. This is a critical consideration for hazardous materials, where a failure of containment could have significant safety and environmental consequences.

Space Efficiency: Their cubic design allows them to be stacked efficiently, both when full and empty. This maximizes warehouse and facility space, a crucial factor in large-scale industrial operations where square footage is at a premium.

Core Function 2: Efficient and Safe Transportation

The “Intermediate Bulk” in IBC signifies its role as a middle ground between small drums and dedicated tanker trucks. This makes it a highly efficient unit for transport.

A Unified Logistics Module: A single stainless steel IBC typically holds 1,000 liters (approximately 275 gallons), replacing four 55-gallon drums. This consolidation drastically reduces the number of individual items that need to be handled, tracked, and moved. Forklift pockets and often stackable designs allow for quick transfer from production lines to trucks and from receiving bays to storage areas.

Reduced Handling Risk: Every time a container is manually handled or decanted, there is a risk of worker injury or spillage. By moving one IBC instead of multiple drums, companies significantly reduce these handling points, enhancing workplace safety and minimizing product loss.

Regulatory Compliance for Shipping: Stainless steel IBCs are often designed and certified to meet international standards for the transport of dangerous goods, such as the UN rating. This makes them a pre-approved, reliable solution for shipping hazardous materials by road, rail, and sea.

Core Function 3: A Versatile Processing Vessel

Perhaps the most advanced function of stainless steel IBCs is their role as active processing vessels. They are not always just passive containers; they are often integral to the production process itself.

Mixing and Blending: Many stainless steel IBCs can be fitted with internal agitators or are designed to be placed on roller beds. This allows for the homogeneous mixing of ingredients, ensuring a consistent blend for products like adhesives, paints, liquid foods, and cosmetic emulsions.

Heating and Cooling: The excellent thermal conductivity of stainless steel allows for efficient temperature control. Tanks can be jacketed to allow a heating or cooling medium (like steam or chilled water) to circulate around the product, facilitating processes like pasteurization, crystallization, or maintaining a specific reaction temperature.

Pressure and Vacuum Operations: The inherent strength of stainless steel enables these tanks to handle both positive and negative pressure. They can be used for applications requiring inert gas blanketing (using nitrogen to prevent oxidation) or for vacuum-filling and degassing operations.

Why Stainless Steel? The Material Advantages

The functions described above are enabled by the unique properties of stainless steel itself. Understanding these properties clarifies why it is the material of choice for so many demanding applications.

Corrosion Resistance: This is the primary advantage. Stainless steel, particularly 316-grade with molybdenum, resists corrosion from a vast array of chemicals, acids, bases, and solvents. This ensures a long service life and prevents tank failure.

Durability and Structural Integrity: The welded construction of a stainless steel IBC creates a robust, single-shell vessel that can withstand the rigors of industrial handling, including stacking, transport vibrations, and minor impacts.

Hygienic and Easy to Clean: The smooth, non-porous surface of stainless steel is easy to clean and sterilize, making it ideal for industries with strict hygiene protocols like food, beverage, pharmaceuticals, and biotechnology. They are often designed with sanitary fittings and can be fully steam-cleaned or Clean-in-Place (CIP).

Temperature Tolerance: Stainless steel maintains its structural integrity across a wide temperature range, from cryogenic applications to high-temperature processes, without degrading or off-gassing.

Practical Benefits in Daily Operations

Beyond their core functions, stainless steel IBCs deliver tangible operational benefits that contribute to a company’s bottom line.

Reusability and Sustainability: Unlike single-use packaging, a well-maintained stainless steel IBC can last for decades. This represents a significant reduction in packaging waste and long-term cost savings. At the end of its life, the steel is fully recyclable.

Total Cost of Ownership (TCO): While the initial investment is higher than plastic alternatives, the durability, reusability, and low maintenance requirements of stainless steel often result in a lower total cost of ownership over its lifespan.

Operational Efficiency: The ability to use one container for storage, transport, and processing creates a seamless workflow. This eliminates the need for time-consuming and potentially contaminating transfer steps between different vessels.

Conclusion: An Industrial Workhorse

The stainless steel IBC tank is far more than a simple container. It is a multifunctional system that consolidates storage, transport, and processing into a single, efficient unit. Its value lies in its ability to protect product integrity, enhance workplace safety, streamline logistics, and actively participate in manufacturing processes. By offering a combination of durability, hygiene, and versatility that other materials cannot match, the stainless steel IBC has rightfully earned its place as an indispensable workhorse across a diverse spectrum of industrial settings. For engineers and operations managers, its primary function is ultimately to provide a reliable, cost-effective, and safe solution for handling the liquids that drive their business.

English

English русский

русский Français

Français Español

Español Deutsch

Deutsch Tiếng Việt

Tiếng Việt