Cement production is a complex and energy-intensive process that generates a significant amount of dust and particulate matter. Managing this dust is essential not only for regulatory compliance but also for worker safety, equipment longevity, and environmental protection. One of the most effective solutions in modern cement plants is the use of industrial filter bag. These components are integral to dust collection systems and play a vital role in ensuring efficient, clean, and safe operations.

Understanding Industrial Filter Bags

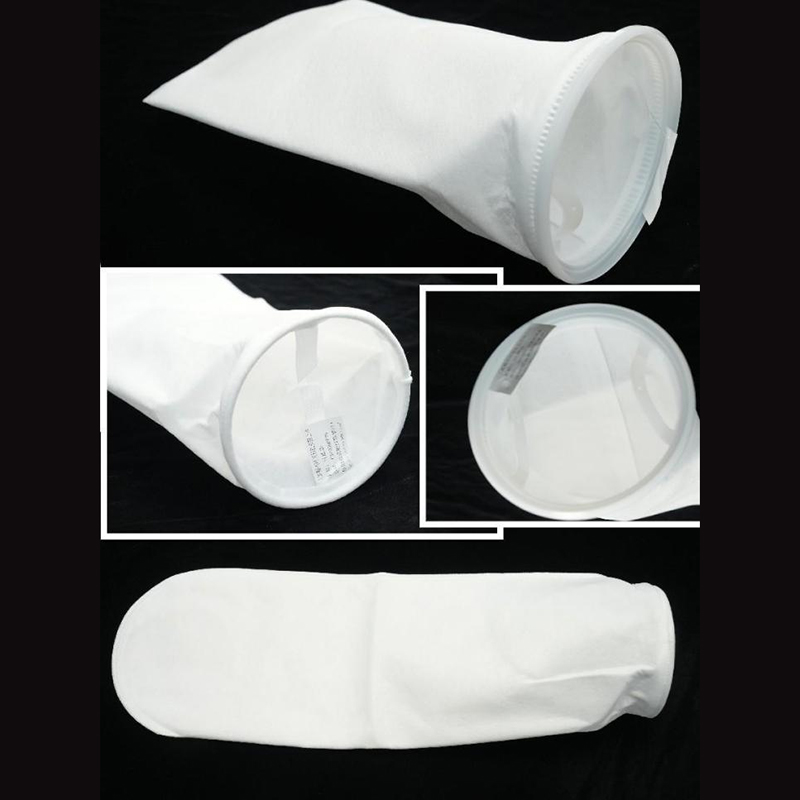

Industrial filter bags are specialized filtration devices designed to capture fine dust particles from the air. They are typically made from high-quality fabrics such as polyester, polypropylene, or other heat-resistant and chemically resistant materials. The bags are installed in baghouse dust collectors, which are commonly used in cement plants to manage the large volumes of dust generated during production.

Filter bags operate on the principle of surface filtration. Dust-laden air passes through the fabric, where particles are trapped on the surface while clean air exits the collector. Over time, a layer of dust, called a dust cake, forms on the filter surface. This layer enhances filtration efficiency by capturing even finer particles. Periodic cleaning of the bags, usually through reverse air pulses or shaking mechanisms, ensures continuous performance without clogging.

Importance of Dust Control in Cement Production

Dust control is a major challenge in cement manufacturing. The production process involves crushing raw materials, grinding clinker, and handling powders such as gypsum and cement. Each stage generates dust that can pose health hazards to workers, damage equipment, and contribute to environmental pollution.

Exposure to cement dust can lead to respiratory issues, skin irritation, and long-term health problems. From an operational perspective, excessive dust accumulation can cause abrasion, equipment malfunction, and reduced efficiency. Industrial filter bags, when properly selected and maintained, provide a reliable solution for capturing these dust particles and minimizing their impact.

Application of Industrial Filter Bags in Cement Plants

Industrial filter bags are used across various stages of cement production. Key applications include:

Raw Material Handling

Crushing and storing raw materials such as limestone and clay generate substantial dust. Filter bags in the baghouse collectors capture this dust, ensuring that the material handling areas remain safe and clean.

Preheater and Kiln Systems

The preheater and kiln sections produce hot exhaust gases laden with fine particulate matter. High-temperature resistant filter bags are essential in these areas to prevent emissions and protect downstream equipment.

Clinker Grinding and Cement Milling

Grinding operations generate ultrafine dust that can escape into the atmosphere if not properly contained. Industrial filter bags in the dust collectors efficiently capture these particles, maintaining air quality and reducing material loss.

Cement Storage and Packing

Handling and packaging of cement powder also produce dust. Filter bags ensure that dust emissions are minimized, protecting workers and reducing cleanup and maintenance requirements.

Advantages of Using Industrial Filter Bags

Using industrial filter bags in cement production provides multiple benefits:

Enhanced Air Quality: By capturing fine dust, filter bags improve indoor air quality in cement plants, ensuring a safer environment for workers.

Regulatory Compliance: Cement plants must meet strict air emission standards. Industrial filter bags help achieve these requirements by effectively controlling particulate emissions.

Operational Efficiency: Efficient dust collection prevents equipment wear and reduces downtime, contributing to consistent production performance.

Material Recovery: Dust captured by filter bags can often be returned to the production process, reducing waste and saving raw materials.

Cost Savings: By preventing equipment damage, reducing maintenance needs, and improving product recovery, filter bags contribute to overall cost efficiency.

Types of Industrial Filter Bags Used in Cement Production

Different cement production processes and dust characteristics require various types of filter bags. Some common types include:

Pulse Jet Bags

These are cleaned using short bursts of compressed air that dislodge the dust cake. They are suitable for high-volume operations and can handle fine dust effectively.

Shaker Bags

These bags use mechanical shaking to remove the dust cake. They are simpler in design but may require more maintenance in high-dust environments.

Reverse Air Bags

Reverse air is blown through the bag to clean it, which is effective for larger or heavier dust particles. These are commonly used in preheater and kiln sections where dust load can be substantial.

Selecting the right bag depends on factors such as dust particle size, temperature, chemical composition, and airflow rates.

Maintenance and Longevity of Filter Bags

Proper maintenance of industrial filter bags is crucial to ensure their efficiency and longevity. Key maintenance practices include:

Regular Inspection: Periodic checks for wear, tears, and fabric degradation help prevent unexpected failures.

Cleaning System Monitoring: Ensuring pulse jet or shaker systems operate correctly maintains consistent dust removal.

Replacement Schedule: Even the best filter bags degrade over time. Replacing bags at the recommended intervals prevents operational issues and keeps dust emissions low.

Environmental Considerations: Proper disposal or recycling of used filter bags is essential to minimize environmental impact.

By following these practices, cement plants can achieve years of reliable service from their filter bags while minimizing downtime and maintenance costs.

Future Trends in Industrial Filter Bag Technology

Advancements in materials and filtration technology continue to enhance the performance of industrial filter bags. Some emerging trends include:

High-Temperature Fabrics: New materials can withstand higher temperatures, allowing filter bags to be used in preheater and kiln exhausts with minimal degradation.

Chemical-Resistant Coatings: Innovative coatings improve resistance to corrosive gases, extending bag life in harsh environments.

Improved Cleaning Mechanisms: Advances in pulse-jet cleaning and vibration systems increase efficiency and reduce maintenance.

Smart Monitoring: Sensors that track differential pressure and airflow can signal when bags need cleaning or replacement, reducing manual inspections and optimizing performance.

These developments help cement plants improve efficiency, reduce emissions, and maintain compliance with environmental standards.

Conclusion

Industrial filter bags play an indispensable role in cement production by controlling dust emissions, enhancing operational efficiency, and protecting worker health. Their applications span raw material handling, kiln exhaust management, grinding operations, and cement packaging. By selecting the right type of filter bag, maintaining it properly, and adopting new technologies, cement plants can achieve cleaner, safer, and more efficient production.

As environmental regulations tighten and production demands increase, the importance of reliable dust filtration will only grow. Industrial filter bags remain a cost-effective, practical, and essential component of modern cement manufacturing operations.

English

English русский

русский Français

Français Español

Español Deutsch

Deutsch Tiếng Việt

Tiếng Việt