The Direct and Critical Link: Filter Bag Surface Area to Dirt Holding Capacity

The relationship between a Filter Bag's surface area and its dirt holding capacity is fundamental, direct, and non-linear. In essence, greater available surface area provides more physical space for particles to collect without prematurely blocking the filtration paths. Dirt holding capacity (DHC) is the total mass of particulate a filter can retain before reaching a terminal pressure drop, and it is the primary determinant of service life. While media type and micron rating set the stage, surface area is the stage's size—dictating how long the performance can run before the filter requires change-out. Understanding this relationship is key to optimizing system cost, labor, and operational stability.

How Surface Area Increases Dirt Holding Capacity

Filtration occurs as contaminated fluid passes through the porous media. Particles are captured within the media's depth (depth filtration) or on its surface (surface filtration). A larger surface area distributes the contaminant load over a greater number of fibers and pore pathways. This prevents localized "hot spots" of clogging. Think of it as a highway: a single lane (small surface area) jams quickly with traffic (particulates), while a multi-lane highway (large surface area) can handle much more traffic before coming to a standstill. The mechanisms at work include:

- Increased Pore Availability: More media means more total pores, allowing a higher volume of particles to be trapped within the 3D matrix without sealing the surface.

- Reduced Face Velocity: For a given flow rate, a larger filter area reduces the fluid's speed as it approaches the media. Lower velocity allows particles to deposit more efficiently and reduces the force that can drive particles into a blinding cake.

- Extended Depth Loading Phase: Filters ideally load particles within their depth before forming a surface cake. A larger area extends this depth-loading phase, which is characterized by a slow, gradual pressure drop increase, maximizing particulate retention.

Key Factors Modifying the Relationship

The correlation is not simply "double the area, double the life." Several factors influence the efficiency of the surface area's utilization.

Media Characteristics

The fabric's construction dictates how it uses its surface. Needle felt media, with a dense, fibrous structure, offers tremendous depth loading and high dirt capacity per square foot. Woven monofilament media, with a more open and straight-through pore structure, tends to move quicker to surface sieving, often resulting in a lower effective capacity per unit area despite similar micron ratings. The fiber type (polyester, polypropylene, nylon) also affects particle adhesion and release characteristics.

Particle Size and Distribution

The nature of the contaminant dramatically impacts the area-capacity dynamic. A slurry containing a high proportion of particles very close to the Filter Bag's micron rating will quickly form a restrictive surface cake, potentially underutilizing the full depth of the media. Conversely, a wide distribution of particle sizes, including many fines, will promote depth loading throughout the media matrix, leveraging the full surface area for a longer time and higher total capacity.

System Operating Conditions

Pressure and flow dynamics are critical. Excessively high differential pressure can compact the collected dust cake or drive particles irreversibly into the media, prematurely consuming its effective porosity and capacity. Stable, designed flow rates ensure the surface area is used as intended.

Practical Implications for Selection and Operation

Ignoring the surface area-to-DHC relationship leads to frequent change-outs, high costs, and process downtime. Here’s how to apply this knowledge constructively.

Selecting the Right Filter Bag Size

When evaluating options, do not default to the smallest bag that fits your housing. Compare the effective filtration area (EFA) of different bag lengths and configurations. For a challenging, high-particulate load, selecting a bag with 30% more EFA can often more than double the service life, reducing change-out frequency and total cost of ownership. Always request DHC test data from your supplier, standardized to a test like ISO 16889 or ASTM F795, to make quantitative comparisons.

Optimizing Multi-Bag Housings

In a multi-bag vessel, ensure all bags have identical specifications and are properly seated. A single bag with a smaller effective area or tighter pore structure will blind first, causing flow to channel through the remaining bags, overloading them and wasting the system's total surface area potential.

Interpreting Pressure Drop Curves

Monitor your system's differential pressure (ΔP). A long, shallow rise in ΔP indicates effective depth loading across a large surface area. A sharp, rapid climb suggests surface blinding, which may indicate the selected bag has insufficient surface area or inappropriate media for the contaminant. The table below contrasts the typical performance profiles:

| Performance Indicator | High Surface Area / Good DHC Utilization | Insufficient Surface Area / Poor DHC Utilization |

| Initial ΔP | Low and stable | May be moderate to high |

| ΔP Increase Rate | Slow and gradual over time | Fast and exponential |

| Primary Loading Mechanism | Depth filtration dominant | Surface cake formation dominant |

| Total Mass Captured at Terminal ΔP | High | Low |

Beyond Simple Area: Advanced Design Enhancements

Manufacturers leverage the surface area principle through advanced designs to push DHC boundaries without drastically increasing bag dimensions.

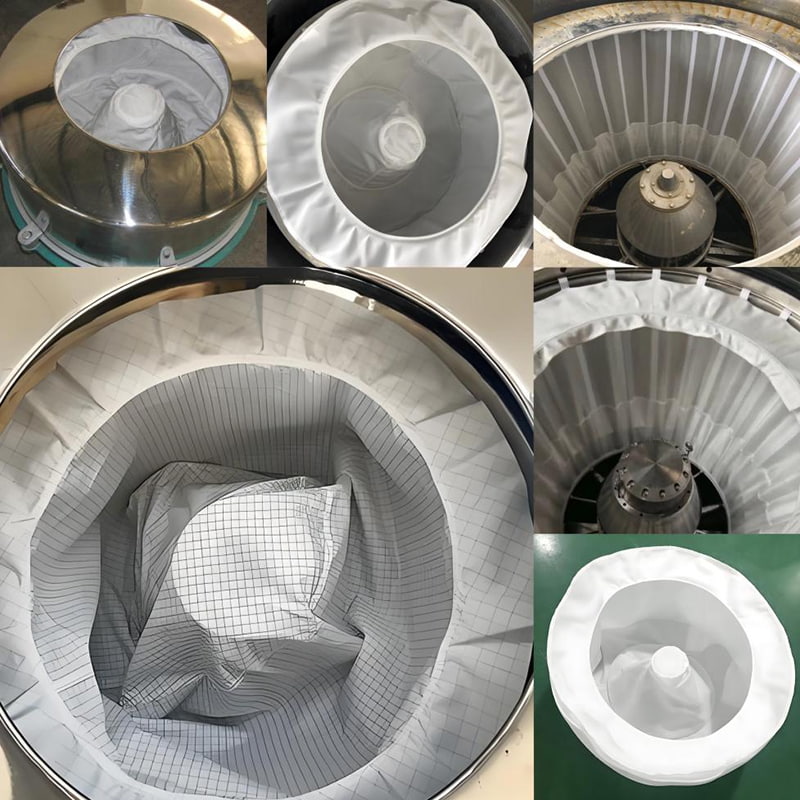

- Pleated Filter Bags: By incorporating pleats, these designs can offer 2-5 times the surface area of a standard gusseted bag of the same nominal length. This is a direct application of maximizing area within a fixed housing footprint.

- Multi-Layer Media Construction: Combining layers of different fiber densities or micron ratings creates a graded pore structure. This guides larger particles to be captured in a coarse, high-capacity outer layer while finer particles are captured deeper within, effectively increasing the usable depth and capacity of the media's total area.

- Controlled Pore Geometry: Engineered media, such as meltblown or spunbond layers with calibrated pore gradients, are designed to load particles more uniformly throughout their thickness, extracting maximum capacity from every square inch of surface area.

Conclusion: A Foundational Design Principle

The relationship between Filter Bags surface area and dirt holding capacity is a cornerstone of effective filtration system design. While not the sole factor, it is a primary and controllable variable. Selecting a Filter Bag with adequate, and often generously sized, effective filtration area is the most straightforward step toward achieving longer service life, lower operational costs, and more stable process performance. By understanding the factors that modulate this relationship—media type, contaminant profile, and system conditions—engineers and plant operators can move beyond trial-and-error and make informed, optimized selections for their specific applications.

English

English русский

русский Français

Français Español

Español Deutsch

Deutsch Tiếng Việt

Tiếng Việt