-

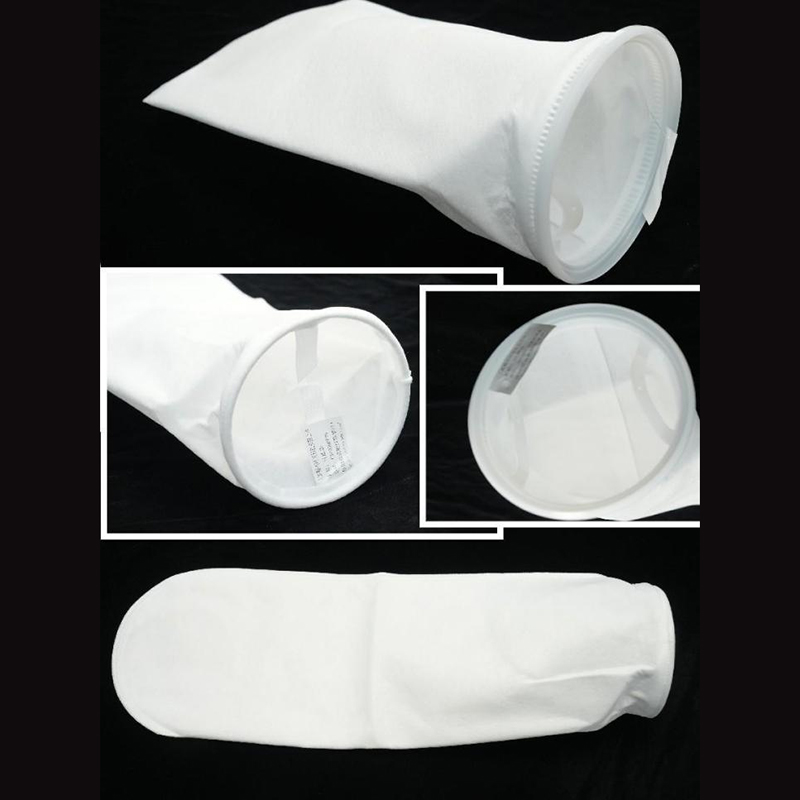

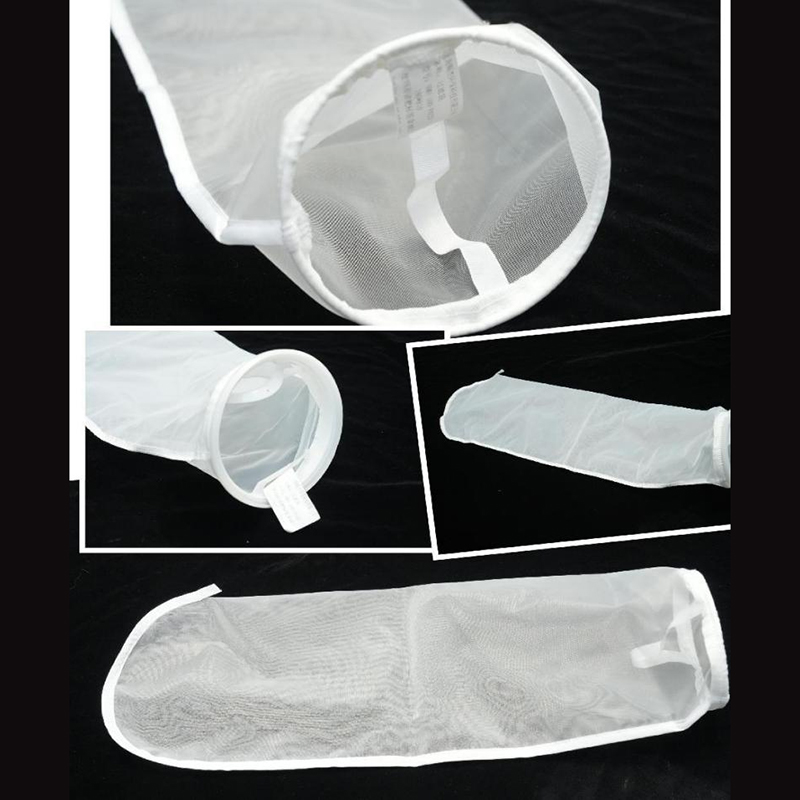

Non-Woven Filter Bags

Non-Woven Filter BagsFilter Bag

-

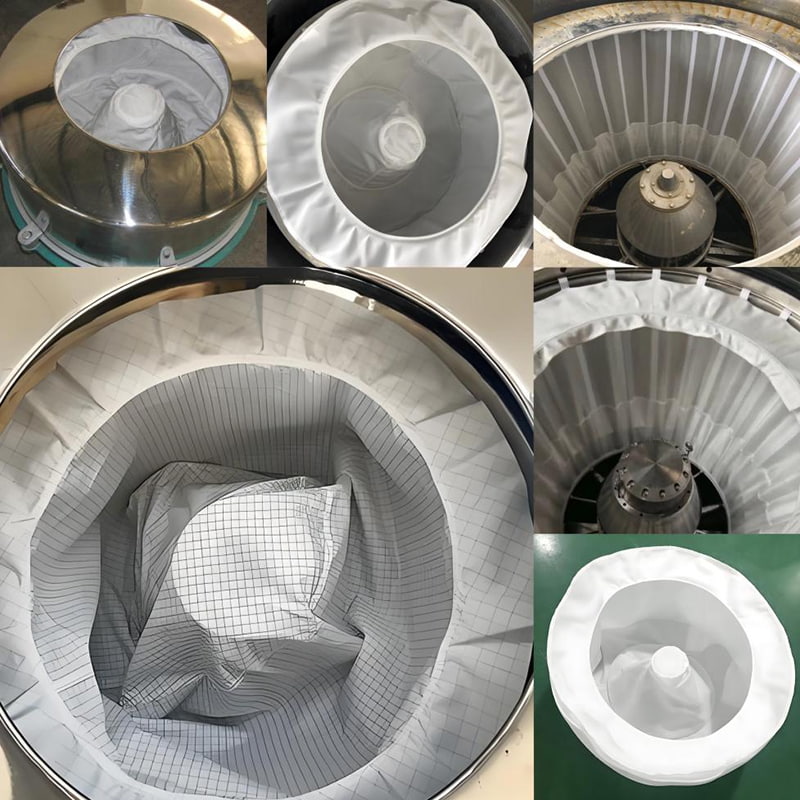

High Density Centrifuge Filter Bags

High Density Centrifuge Filter BagsFilter Bag

-

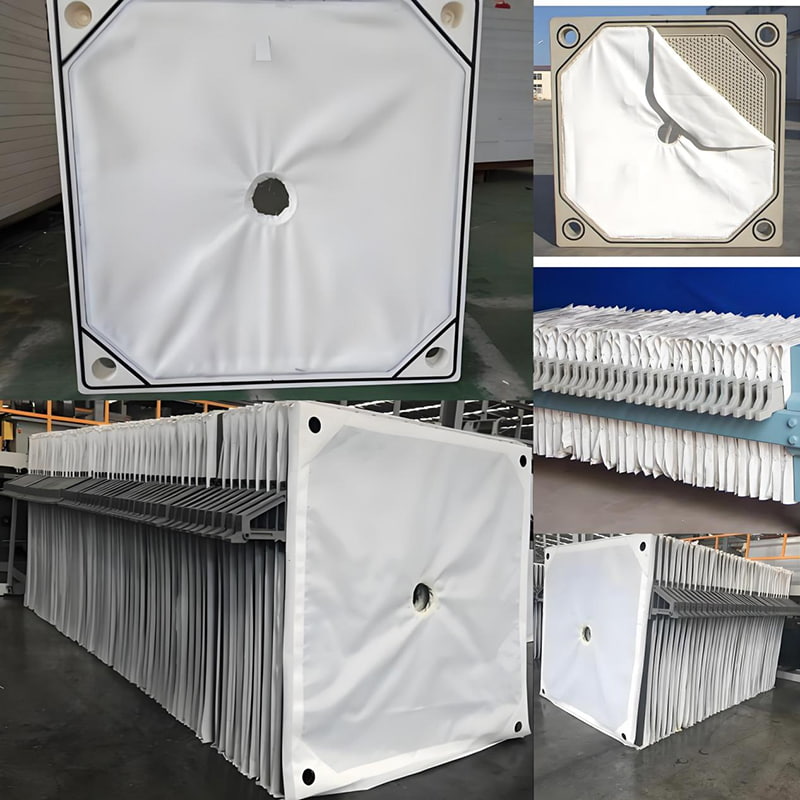

Plate and Frame Filter Cloth

Plate and Frame Filter ClothFilter Bag

Products & Solutions

CONTACT US

-

+86 182 1733 6020

-

-

No.7 Industrial Park, Xiayuan Town, Rugao City, Jiangsu Province

Filter Bags Manufacturer

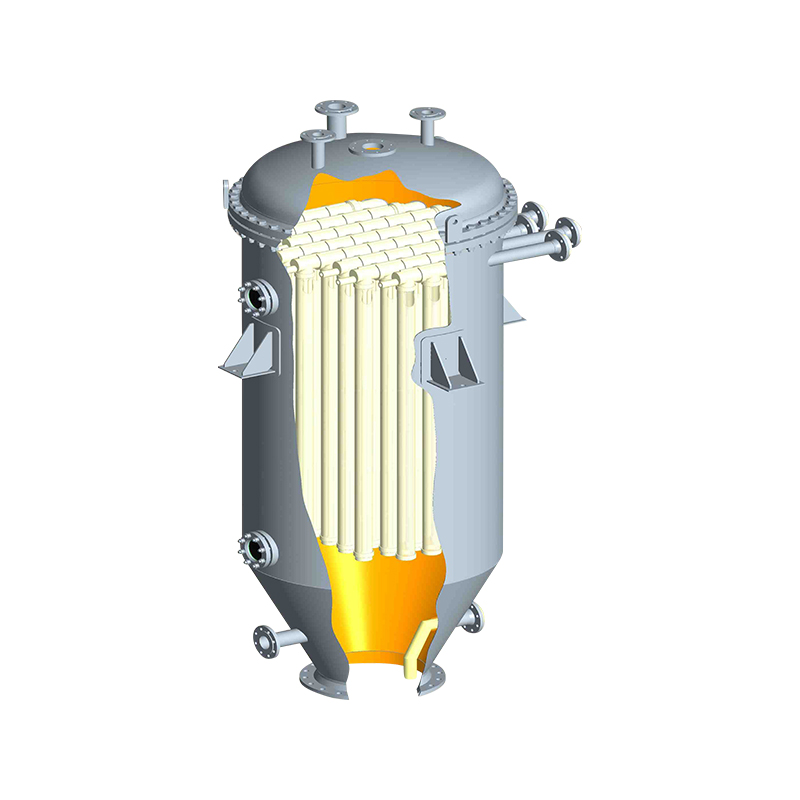

The bag filter has the outstanding characteristics of economic consumption, low-pressure drop, and convenient replacement operation, which is suitable for most conventional precision filtering occasions. Fitel bag is the core of the TF series bag filter system, which directly determines the filtration performance and the quality of final products. Cifie has developed four series of filter bags with different characteristics by using the global high-quality filter substrate to optimize the proportion, which can fully meet the strict requirements of precision filtration. All filter bags are made in a clean production environment and pass strict quality control procedures. Efficient filtration performance and stable quality are two main characteristics of the ciie filter bag. The selection of city filter bags means the selection of an efficient and reliable filtration process.

About Cijie

Rugao Cijie Environmental Technology Co.,Ltd. is a China Industrial Baghouse Filter Bag Manufacturer and factory. It focuses on precision filtration, self-cleaning filtration, and sewage treatment equipment, and is committed to providing comprehensive professional filtration support for customers. The core technology team of Cijie has rich industry filtration experience, strong design and research ability, comprehensive use of comprehensive filtration products, and integration of global Into filter technology and product resources, to provide a one-stop solution.

With advanced technical strength and efficient service, we have established close cooperation with several well-known international brands, with a strong competitive advantage, to provide reliable protection for customer cooperation. We can offer custom Baghouse Filter Bags, Industrial Filter Bags

Shanghai Cijie filtration products are widely used in the petrochemical industry, sewage treatment, fine chemical industry, pharmacy, food and beverage, automobile industry, coating, papermaking, and other fields.

Shanghai Cijie Environmental Technology Co., Ltd. takes the principle of "science and technology leading, quality excellence" as the principle, and "serves users and returns to nature" as its purpose. It provides high-quality services for customers. The company has independent import and export operation rights and facilitates customer service at home and abroad. Welcome to visit Industrial Filter Bags factory

Latest news and exhibitions

-

05 Feb, 2026

05 Feb, 2026What Are Bag Filters? Complete Guide to Industrial Filtration

Bag filters are cylindrical or tubular filtration devices designed to remove particulate matter from gas or liquid streams in industrial processes. T...

Read more -

30 Jan, 2026

30 Jan, 2026Combining Automatic Candle Filter Strategies for Cleaner Trading Signals

Automatic Candle Filter tools are designed to reduce market noise by analyzing candlestick structures and filtering out low-quality price movements. T...

Read more -

23 Jan, 2026

23 Jan, 2026High-Performance Non-Woven Filter Bags: Selection, Applications, and Maintenance

Introduction to Non-Woven Filter Bags Non-woven filter bags have become essential components in industrial filtration systems. They are used extensive...

Read more

Industry Knowledge Extension

Filter Bag

How does the design of the filter bag prevent clogging or blinding during filtration processes?

The design of filter bag plays a crucial role in preventing clogging or blinding during filtration processes, ensuring consistent performance over time. Here are some key design features that help mitigate these issues:

Gradual Layered Filtration:

Many filter bags are designed with multiple layers of filtration media, allowing for progressive filtration. Coarser particles are captured in the outer layers, while finer particles are trapped in the inner layers. This prevents rapid clogging by distributing the particulate load across multiple layers.

Surface and Depth Filtration:

Surface filtration captures particles on the surface of the filter, while depth filtration allows particles to penetrate into the media. Depth filtration is particularly effective in reducing clogging, as particles are captured throughout the filter's thickness, rather than just on the surface.

High-Quality Filter Media:

The use of high-quality, carefully selected filter media (such as polypropylene, polyester, or PTFE) helps to minimize clogging. These materials are designed to handle large volumes of particles without significant resistance, allowing for a smoother flow and less frequent clogging.

Optimized Pore Structure:

Filter bags with an optimized pore size distribution provide better filtration efficiency. By balancing small and large pores, the filter can trap a wide range of particle sizes without causing an excessive buildup of material that leads to clogging.

Anti-Clogging Coatings:

Some filter bags are treated with special anti-clogging coatings that reduce the adherence of particles to the surface. This helps to prevent the buildup of particles that can eventually block the filter media.

Self-Cleaning Design:

Certain filter bag systems include a self-cleaning mechanism. These systems periodically reverse the flow or shake the filter bag to dislodge accumulated particles, preventing clogging and maintaining a steady filtration rate.

Tapered or Cone Shape:

The design of the filter bag, such as a tapered or cone-shaped construction, helps distribute particulate matter more evenly across the filter media, which can help prevent concentrated buildup in one area and reduce the risk of clogging.

High Flow Rate Design:

Some filter bags are designed to support high flow rates without causing significant pressure drop, ensuring that particles are efficiently filtered without creating blockages that slow down the process.

By integrating these design elements, filter bags can maintain high filtration efficiency and reduce the likelihood of clogging or blinding, extending their service life and reducing downtime for maintenance.

English

English русский

русский Français

Français Español

Español Deutsch

Deutsch Tiếng Việt

Tiếng Việt