-

Liquid Single Core Filter

Liquid Single Core FilterElement Filter

-

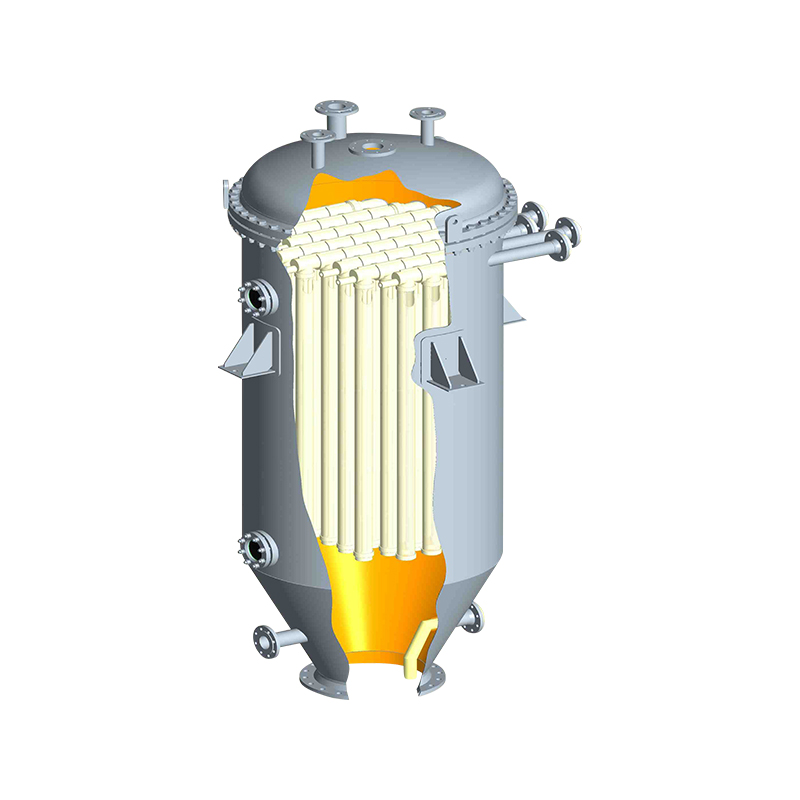

Liquid Multi-Core Filter

Liquid Multi-Core FilterElement Filter

-

Single-Core and Multi-Core Gas Filters

Single-Core and Multi-Core Gas FiltersElement Filter

Products & Solutions

CONTACT US

-

+86 182 1733 6020

-

-

No.7 Industrial Park, Xiayuan Town, Rugao City, Jiangsu Province

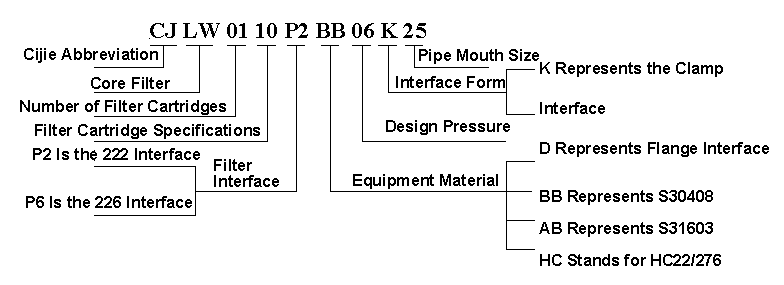

Cartridge Filter Housing Manufacturer

The CJLW series core filter uses a filter element as the filtering element, which is suitable for liquid precision filtration and gas filtration, removing trace impurities and bacteria. It has the advantages of high precision, high efficiency, and large pollutant capacity. The LW filter is equipped with a variety of high-performance filter cartridges, which can meet various conventional and special precision filtration requirements.

The CJLW series core filters can be equipped with melt blown filter cartridges, wire wound filter cartridges, PP folded film filter cartridges, PTFE filter cartridges, metal sintered filter cartridges and titanium rod sintered filter cartridges, high flow filter cartridges, and more.

The CJLW series core filters are divided into single core filters and multi-core filters, and the materials include stainless steel SS304 \ SS316, HC22, 2205, PP and other materials.

Application scope

◆ Applicable industries: fine chemicals, water treatment, papermaking, food and beverage, automotive coating, petrochemicals, mechanical processing, pharmaceuticals, coatings, electronics, etc

◆ Applicable liquids: Widely applicable, various liquids containing trace impurities

Main filtering function: remove particles of various sizes,

◆ Filtration type: Adopting replaceable filter element for filtration, manually replacing the filter element regularly

Professional filtration system

About Cijie

Rugao Cijie Environmental Technology Co.,Ltd. is a China Stainless Steel PP Cartrdige Filter Housing Manufacturer and factory. It focuses on precision filtration, self-cleaning filtration, and sewage treatment equipment, and is committed to providing comprehensive professional filtration support for customers. The core technology team of Cijie has rich industry filtration experience, strong design and research ability, comprehensive use of comprehensive filtration products, and integration of global Into filter technology and product resources, to provide a one-stop solution.

With advanced technical strength and efficient service, we have established close cooperation with several well-known international brands, with a strong competitive advantage, to provide reliable protection for customer cooperation. We can offer custom Stainless Steel Cartridge Filter Housing(ss304, ss316), PP Cartrige Filter Housing, single multi core cartridge filter housing

Shanghai Cijie filtration products are widely used in the petrochemical industry, sewage treatment, fine chemical industry, pharmacy, food and beverage, automobile industry, coating, papermaking, and other fields.

Shanghai Cijie Environmental Technology Co., Ltd. takes the principle of "science and technology leading, quality excellence" as the principle, and "serves users and returns to nature" as its purpose. It provides high-quality services for customers. The company has independent import and export operation rights and facilitates customer service at home and abroad. Welcome to visit Stainless Steel Cartridge Filter Housing factory

Latest news and exhibitions

-

05 Feb, 2026

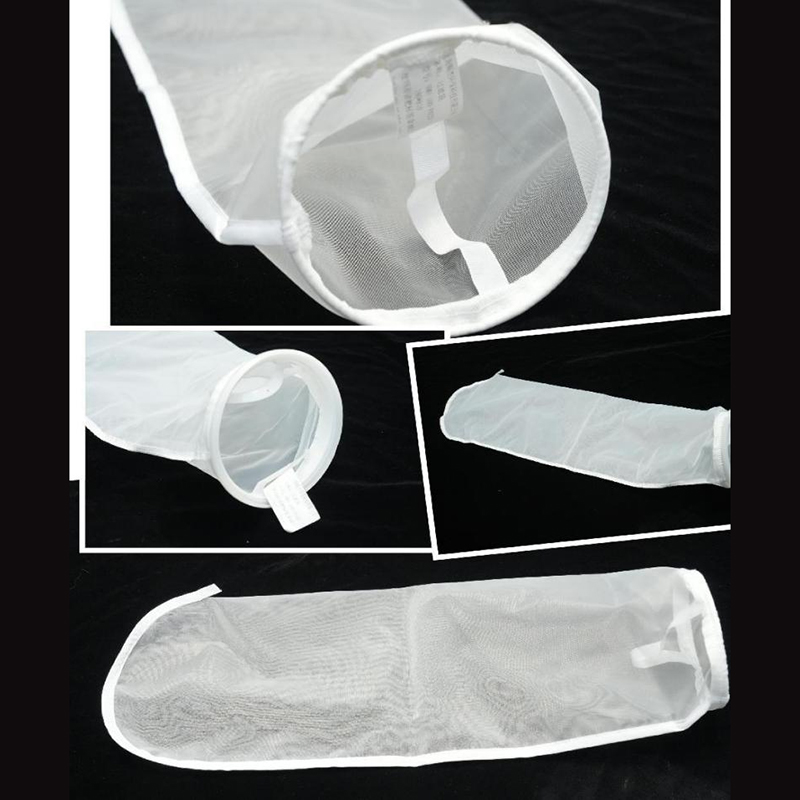

05 Feb, 2026What Are Bag Filters? Complete Guide to Industrial Filtration

Bag filters are cylindrical or tubular filtration devices designed to remove particulate matter from gas or liquid streams in industrial processes. T...

Read more -

30 Jan, 2026

30 Jan, 2026Combining Automatic Candle Filter Strategies for Cleaner Trading Signals

Automatic Candle Filter tools are designed to reduce market noise by analyzing candlestick structures and filtering out low-quality price movements. T...

Read more -

23 Jan, 2026

23 Jan, 2026High-Performance Non-Woven Filter Bags: Selection, Applications, and Maintenance

Introduction to Non-Woven Filter Bags Non-woven filter bags have become essential components in industrial filtration systems. They are used extensive...

Read more

Industry Knowledge Extension

Element Filter

How does the element filter perform under fluctuating flow conditions?

An element filter’s performance under fluctuating flow conditions depends on its design, filter media, and operating principles. Here's how it typically behaves:

Pressure Drop Variations:

Fluctuating flow rates can lead to changes in pressure across the filter. When flow increases, the pressure drop tends to rise as more liquid or gas passes through the filter media, which may lead to reduced filtration efficiency or even bypassing of contaminants if the system isn’t designed to handle it.

Filters with high-quality filter cartridges, especially those designed for high flow or precision filtration, are engineered to minimize pressure drops and maintain performance during such fluctuations.

Efficiency of Filtration:

Under low flow rates, the element filter can typically perform well, capturing even the smallest particles efficiently.

At high flow rates, there’s a risk that the filter may not capture all impurities as effectively, especially if the flow exceeds the filter’s rated capacity. This can result in shortened filter life or incomplete filtration if particles are pushed through the media too quickly.

Impact on Filter Media:

Some types of filter media, such as melt blown or PP folded film, may compress or deform under high pressure caused by fluctuating flow rates, potentially reducing their effectiveness.

Metal sintered or titanium rod sintered cartridges are typically more resistant to fluctuations and can maintain a more consistent filtration performance under varying pressures and flow rates.

Adaptive Filtration Systems:

More advanced filters or systems might have automatic flow control mechanisms or pressure regulation features that help stabilize performance during fluctuations. Without these, manual adjustments may be required to optimize flow and pressure.

In multi-core filters, having multiple filter elements can help distribute the flow more evenly, reducing the strain on individual cartridges during fluctuating conditions.

Bypass Risk:

In cases of extreme fluctuations, especially if the flow exceeds the design limits, there is a risk that unfiltered liquid or gas may bypass the filter media, leading to reduced filtration quality. Filters with bypass valves or other safety mechanisms can help prevent this.

Design Considerations:

Filters designed for industries with variable flow rates (e.g., petrochemical or mechanical processing) typically have high-strength materials, rigid filter media, and supportive housing to withstand rapid fluctuations without compromising filtration quality.

Element filter generally perform well under fluctuating flow conditions if they are designed for such environments. To ensure consistent performance, you should choose filters with durable filter media, consider multi-core systems for high flow applications, and verify that the filter is rated for the expected range of flow fluctuations. Filters with pressure indicators or regulators are also helpful in maintaining efficiency during flow changes.

English

English русский

русский Français

Français Español

Español Deutsch

Deutsch Tiếng Việt

Tiếng Việt