In industrial production and daily life, filtration is a crucial operation. It can remove impurities from liquids or gases, ensuring product quality and the smooth progress of the production process. Automatic Candle Filter, as an advanced filtering device, is gradually emerging in various fields and playing an irreplaceable role.

Analysis of Working Principle

Core filtration structure

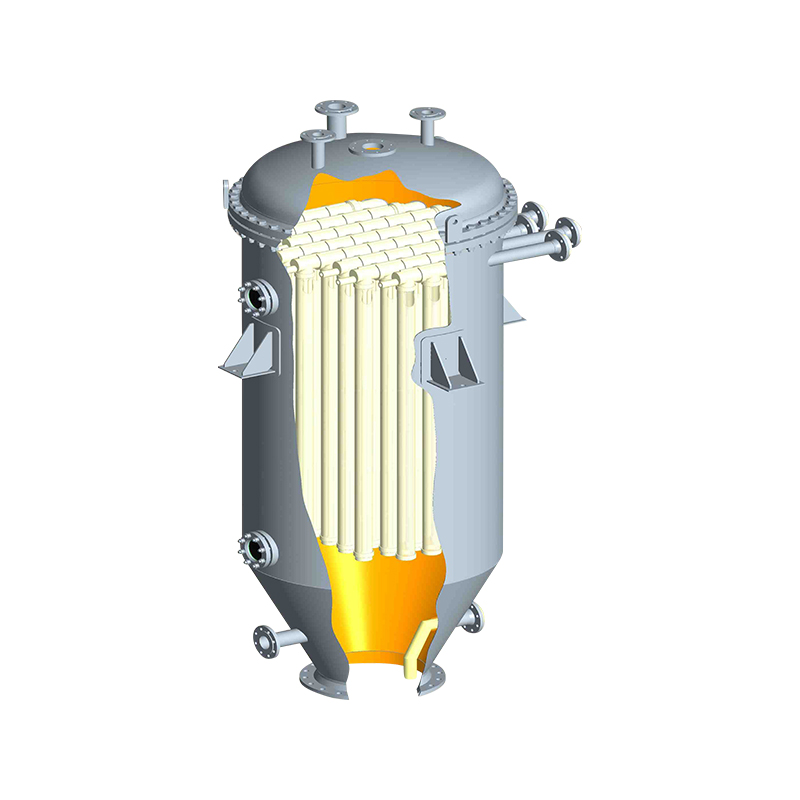

The Automatic Candle Filter is mainly composed of a sealed container and multiple candle-shaped filter elements inside. These filter elements are usually made of metal, polymer materials or other special materials, and their surfaces are covered with one or more layers of filtering media, such as filter cloth, metal mesh, porous ceramics, etc. The design forms of filter elements are diverse, with common ones including plum blossom-shaped and tubular shapes. The unique structural design aims to increase the filtration area and enhance the filtration efficiency.

Detailed explanation of the filtration process

When the liquid or gas to be filtered is sent into the interior of the filter through power equipment such as pumps, the material will be evenly distributed around the filter element. Under the effect of pressure difference, liquid or gas passes through the filter medium on the surface of the filter element, while solid particles, impurities, etc. are intercepted on the surface of the filter medium. As the filtration continues, impurities gradually accumulate on the surface of the filter element, forming a "filter cake layer". Due to the extremely small gaps between the particles in the filter cake layer, it can further prevent even finer impurities from passing through, thereby achieving a high-precision filtration effect and ensuring that the liquid or gas passing through the center of the filter element and discharged from the clear liquid outlet reaches the required purity. Before the filter cake layer is formed, the "clear liquid" discharged usually returns to the raw material inlet through the circulation pipeline and is sent back to the filter for circulation filtration until the filter cake layer reaches a certain thickness and meets the filtration requirements. At this point, the system will automatically send a signal to control the clear liquid to stop circulation and instead send it to the next process.

Reverse blow cake removal and slag discharge process

After normal filtration for a period of time, the thickness of the filter cake layer keeps increasing, which will cause the rate at which the filtrate passes through the filter cake layer to decrease and the filtration efficiency to deteriorate. At this point, reverse blowing to remove the filter cake operation is required. The system will automatically start the back-blowing program based on the pressure difference between the inlet and outlet detected by the pressure sensor or the preset filtration time and other signals. The reverse-blowing medium is generally compressed air, nitrogen or saturated steam. These high-pressure gases are blown out in reverse from the inside of the filter element. The powerful impact force of the airflow causes the filter cake adhering to the surface of the filter element to fall off rapidly. After the reverse blowing is completed, the sludge discharge valve at the bottom of the filter will automatically open, and the fallen filter cake and the remaining liquid will be discharged from the filter together. After the slag discharge is completed, close the slag discharge valve, and the filter returns to its initial state, preparing for the next round of filtration cycle.

Notable features and advantages

Highly automated

The Automatic Candle Filter is equipped with an advanced PLC control system, which can realize the automatic operation of the entire filtering process. From feeding, filtration, reverse blow cake removal to residue discharge and other links, all can be automatically executed through pre-set programs without excessive manual intervention. This not only significantly reduces labor costs, but also enhances production efficiency and the stability of the filtration process, lowering the risks caused by human operational errors. For instance, in continuous production chemical enterprises, automatic candle filters can operate stably for 24 hours without interruption according to the production rhythm, ensuring the continuity of production.

High-efficiency filtration performance

Large filtration area: The design of multiple candle-shaped filter elements enables the filter to have a large filtration area, allowing it to handle a large amount of material within a unit of time. Compared with traditional filtration equipment, under the same time and space conditions, the automatic candle filter can filter more liquids or gases, greatly enhancing production capacity.

High-precision filtration: By choosing the appropriate filtration medium and filter element structure, the automatic candle filter can achieve extremely high filtration accuracy, meeting the application scenarios with strict requirements for filtration accuracy. Its filtration accuracy can reach up to 0.22 microns, effectively removing tiny particles, bacteria, colloids and other impurities from liquids or gases, ensuring the quality and purity of the products. For instance, in the pharmaceutical industry, the filtration requirements for liquid medicine are extremely high. The automatic candle filter can precisely filter out particles and bacteria in the liquid medicine, ensuring the safety and effectiveness of the drugs.

High dirt-holding capacity: As the filter cake layer formed on the surface of the filter element can continuously accumulate impurities, the automatic candle filter has a strong dirt-holding capacity and can handle materials with a high impurity content. This makes it widely applied in industries with a high content of raw material impurities, such as sewage treatment and mining.

Closed operation and environmental friendliness

The entire filtration process takes place in a sealed container, effectively preventing material leakage and evaporation, reducing environmental pollution, and also ensuring the safety of operators. This closed design is particularly important when handling corrosive, volatile or toxic and harmful materials. For instance, when dealing with wastewater containing heavy metal ions, the automatic candle filter can ensure that the wastewater does not leak during the filtration process, thus avoiding pollution to the surrounding environment.

Versatility

The automatic candle filter is equipped with multiple functions. Besides the conventional direct filtration, it can also perform pre-coating filtration, slurry concentration, filter cake recovery and filter cake washing, etc. Pre-coated filtration involves applying a layer of filter aid, such as diatomite or activated carbon, on the surface of the filter medium in advance to enhance filtration accuracy and effectiveness. The slurry concentration function can gradually separate the liquid in the slurry through continuous circulation and filtration, thereby increasing the concentration of the slurry. The filter cake recovery function can recover valuable filter cakes from liquids with high solid content, achieving resource reuse. The filter cake washing function can wash the intercepted filter cake multiple times inside the filter, further improving the purity and quality of the filter cake.

Easy maintenance and low failure rate

The main structure of the equipment is relatively simple. The main moving parts are concentrated in the back-blowing system, and the back-blowing operation adopts a dynamic mode, which makes the failure rate of the equipment relatively low. Meanwhile, the replacement of vulnerable parts such as filter elements is relatively convenient. Maintenance personnel can complete the maintenance work in a short time, reducing the downtime of the equipment and improving production efficiency. Moreover, the filter elements are usually designed in groups, which not only reduces the air consumption of each backblowing but also conveniently isolates the damaged filter elements, without affecting the normal operation of the entire filtration system.

Wide range of application fields

The food and beverage industry

Juice production: During the juice production process, automatic candle filters can effectively remove impurities such as fruit residue, suspended matter, and microorganisms from the juice, making the juice clearer and more transparent with a purer taste. At the same time, it can also extend the shelf life of the juice and enhance the market competitiveness of the product. For instance, in the production of fruit juices such as apple juice and grape juice, through the filtration of automatic candle filters, fine fruit pulp particles and pectin in the juice can be removed, significantly enhancing both the appearance and taste of the juice.

Alcoholic beverage brewing: For the brewing of alcoholic beverages such as beer and wine, automatic candle filters can filter out impurities such as yeast, bacteria, and proteins in the liquor, making the liquor clearer and the taste more mellow. During the beer brewing process, the filtration stage plays a crucial role in the clarity and foam stability of the beer. The automatic candle filter can precisely control the filtration accuracy to ensure the stability of the beer's quality.

Edible oil processing: During the refining process of edible oil, automatic candle filters can remove impurities such as phospholipids, gums, pigments, and odorous substances from the oil, thereby enhancing the purity and quality of the edible oil. Whether it is the processing of vegetable oils such as soybean oil, corn oil and olive oil, or animal fats, automatic candle filters can play a significant role in helping to produce high-quality edible oils that meet national standards.

The pharmaceutical and biopharmaceutical industry

Active pharmaceutical ingredient (API) production: During the API production process, high-precision filtration of reaction solutions, extracts, etc. is required to remove impurities, catalyst residues, etc. The automatic candle filter can meet this requirement, ensuring the purity and quality of the active pharmaceutical ingredient and providing a guarantee for the safety and efficacy of the drug. For instance, in the production of raw materials such as antibiotics and vitamins, automatic candle filters can effectively filter out impurities generated during the reaction process, thereby enhancing the purity of the raw materials.

Biopharmaceuticals: In the field of biopharmaceuticals, such as the production of vaccines and antibody drugs, the requirements for the filtration environment and filtration accuracy are extremely high. The closed operation and high-precision filtration performance of the automatic candle filter can effectively prevent microbial contamination and ensure the quality and safety of biological products. During the vaccine production process, it is necessary to filter the culture medium containing viruses or bacteria. The automatic candle filter can perform efficient filtration in a sterile environment, ensuring the quality and safety of the vaccine.

Pharmaceutical preparations: During the production process of pharmaceutical preparations, such as tablets, capsules, and injections, automatic candle filters can be used to filter out particles, bacteria and other contaminants in the liquid medicine, ensuring that the quality of the drugs meets relevant standards. Especially for the production of injections, the requirements for the purity and sterility of the drug solution are extremely strict. The automatic candle filter is one of the key devices to ensure the quality of drugs.

The chemical and petrochemical industry

Chemical raw material production: During the production process of chemical raw materials, various impurities are often generated. The automatic candle filter can filter the chemical raw materials, improve the purity of the raw materials, and ensure the smooth progress of subsequent chemical reactions. For instance, in the production of chemical raw materials such as sulfuric acid, hydrochloric acid and nitric acid, automatic candle filters can remove impurities like metal ions and suspended solids, thereby enhancing the quality of the chemical raw materials.

Catalyst recovery: In the production processes of petrochemicals and some fine chemicals, the use of catalysts is very common. The automatic candle filter can filter the reaction liquid containing catalysts, achieving the recovery and reuse of catalysts, reducing production costs, and at the same time minimizing environmental pollution. For instance, in the catalytic cracking reaction during the petroleum refining process, the automatic candle filter can effectively recover the catalyst and enhance its utilization rate.

Polymer production: During the production process of polymers, such as polyethylene, polypropylene and other plastics, automatic candle filters can remove impurities and gel particles from polymer solutions, ensuring the quality and performance of polymer products. By precisely controlling the filtration accuracy, high-quality polymer products can be produced to meet the usage requirements of different fields.

Environmental protection and water treatment industry

Wastewater treatment: Automatic candle filters can be used to treat various industrial wastewater and domestic sewage, effectively removing solid suspended matter, organic matter, heavy metal ions and other pollutants in the sewage, so that the treated water meets the discharge standards or reuse requirements. In the treatment of industrial wastewater such as electroplating wastewater, printing and dyeing wastewater, and chemical wastewater, automatic candle filters can efficiently remove multiple pollutants from the wastewater through different filter media and process combinations. For the treatment of domestic sewage, automatic candle filters can also be used as advanced treatment equipment to further improve the effluent quality and achieve the reuse of reclaimed water.

Drinking water purification: During the purification process of drinking water, automatic candle filters can remove impurities such as sediment, rust, colloids, and bacteria from the water, improving the taste and safety of drinking water. Especially in areas with poor water source quality, automatic candle filters can serve as important equipment for drinking water purification, providing residents with clean and safe drinking water.

Other industries

In the electronics industry, the requirements for the preparation of ultrapure water and the filtration of electronic chemicals are extremely high. The automatic candle filter can be used to remove impurities such as tiny particles, bacteria and organic matter from ultrapure water, ensuring the strict water quality requirements of processes such as electronic chip manufacturing. Meanwhile, during the production and use of electronic chemicals, automatic candle filters can also filter electronic chemicals to ensure their purity and quality and prevent impurities from causing damage to electronic components.

In the mining industry, automatic candle filters can be used for the filtration of ore leachate and the treatment of tailings wastewater, etc. Through filtration, valuable metals in the ore leachate can be recovered, and at the same time, the tailings wastewater can be discharged up to standard, reducing environmental pollution. For instance, during the mining and smelting of metals such as gold and copper, automatic candle filters can filter the leachate, thereby enhancing the recovery rate of metals.

In the coatings and inks industry: During the production process of coatings and inks, automatic candle filters can remove particulate impurities, gels, etc., ensuring the uniformity, fluidity, gloss and other properties of coatings and inks. By precisely controlling the filtration accuracy, high-quality coating and ink products can be produced to meet the needs of different customers. Whether it is architectural coatings, automotive coatings or printing inks, etc., automatic candle filters play an important role in quality assurance.

English

English русский

русский Français

Français Español

Español Deutsch

Deutsch Tiếng Việt

Tiếng Việt